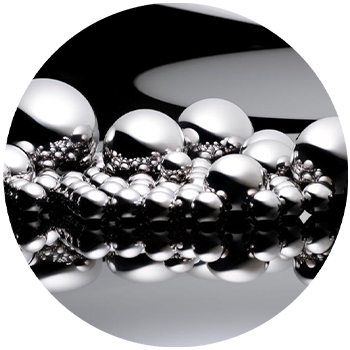

MATERIALS

Premium quality, on par with the main brands, ensured by the best European suppliers, in compliance with the highest international quality standards (ISO 683-17):

- 100Cr6

- 100CrMnSi6-4

- 100CrMo7-3

- 100CrMo7

Traceability of the raw material up to casting (3.1 certificates).

Use of forgers specialized in the sector (Hot-rolling technology).

Optional: Possibility of using materials optimized according to the application (Remediation: 100Cr6A; Cementation: SAE4320, SAE3311, SAE8620; Stainless: Cronidur 30, M50, AISI440C ...).

Our special processes meet the highest standards of quality and performance.